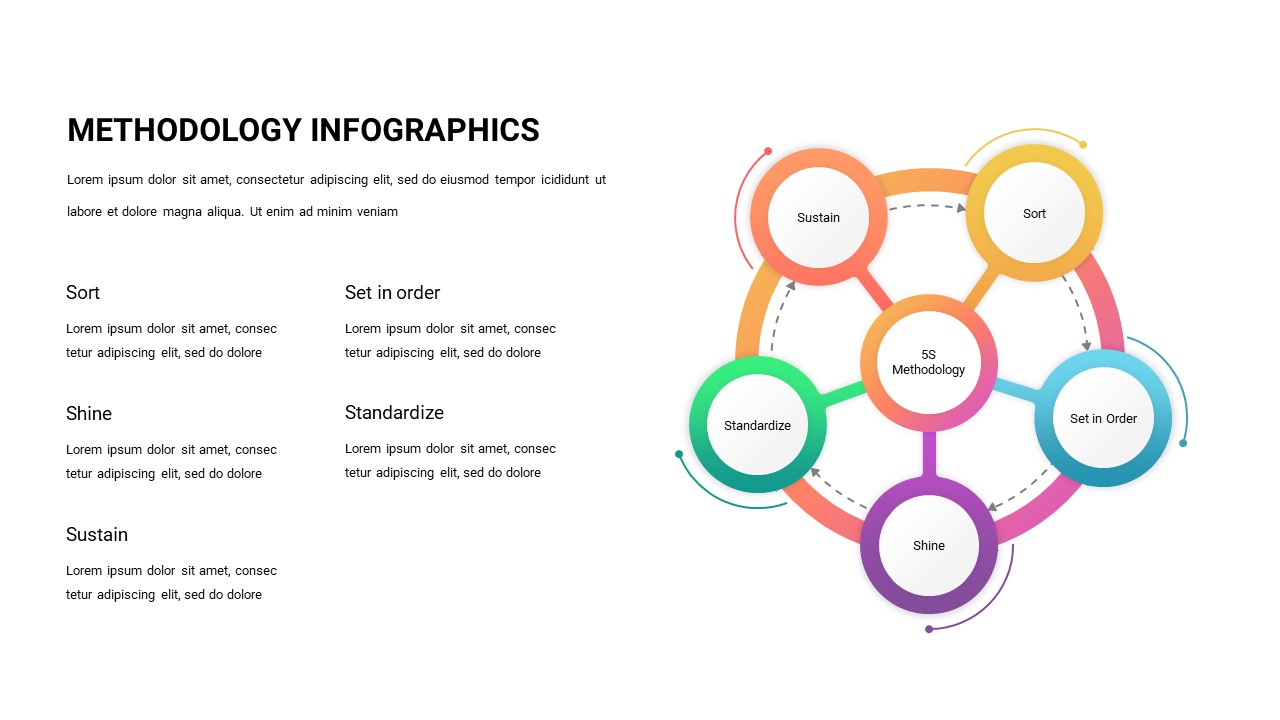

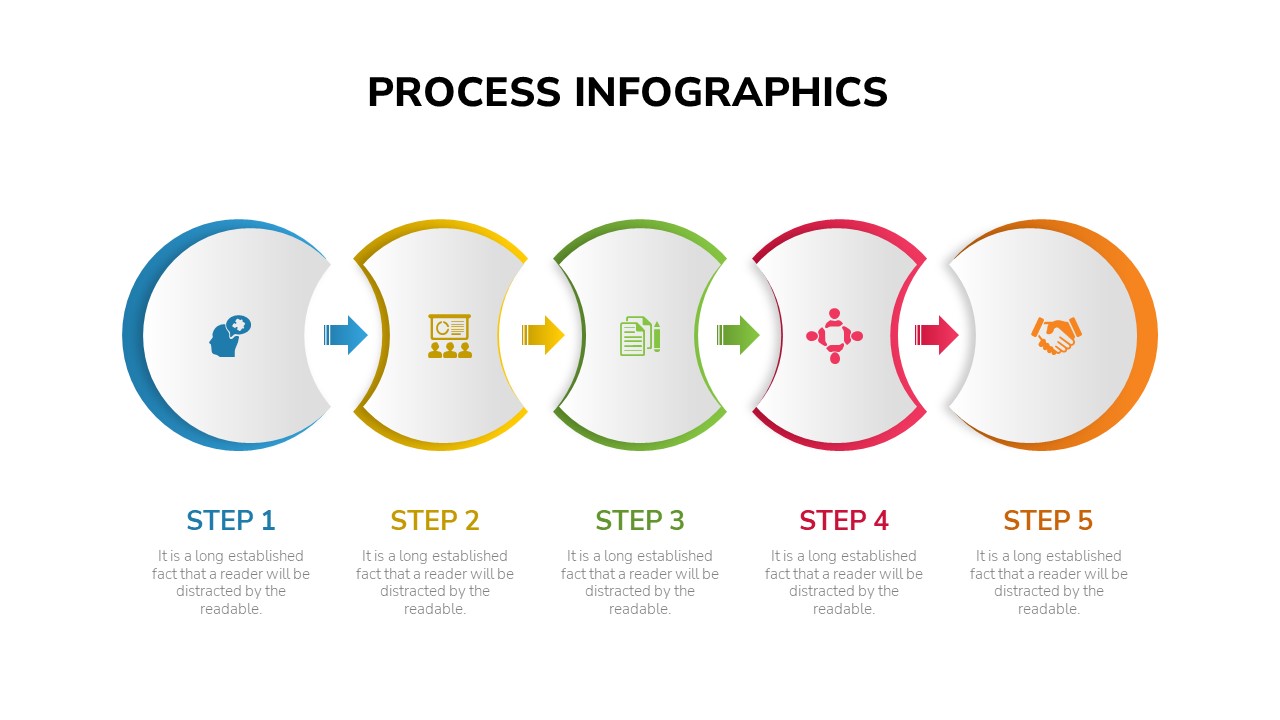

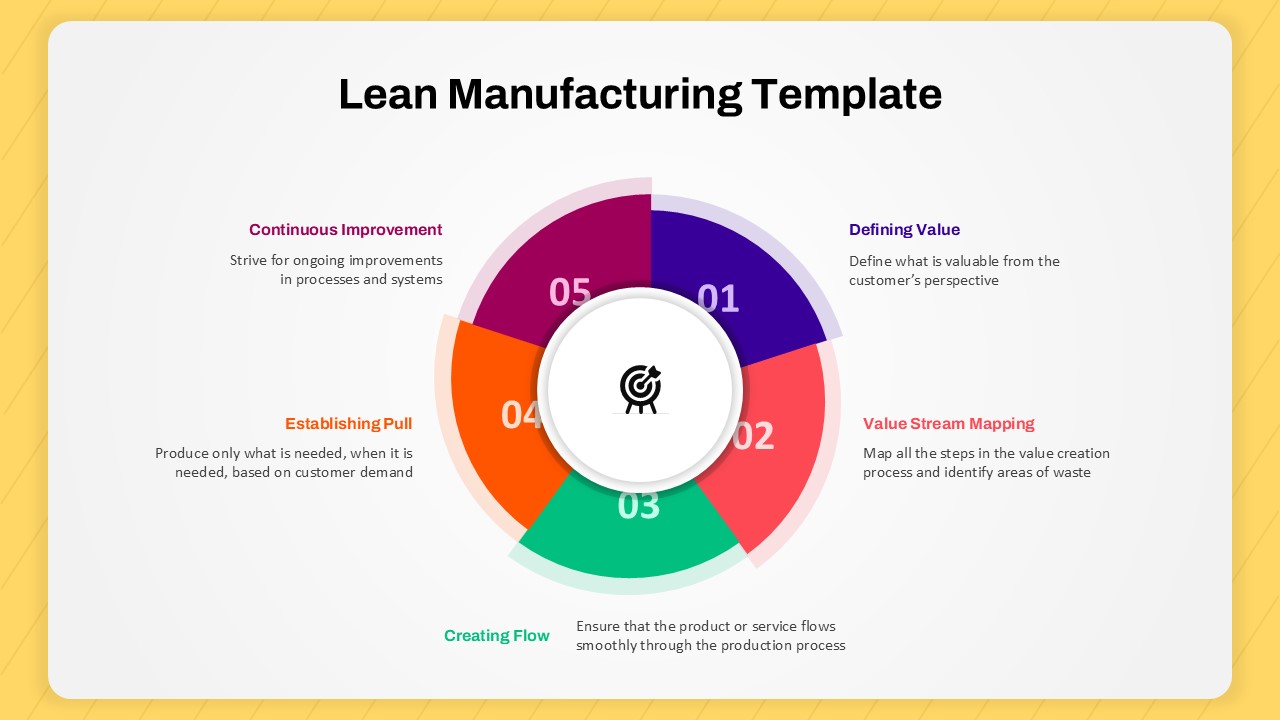

5 Principles Of Lean Manufacturing Template

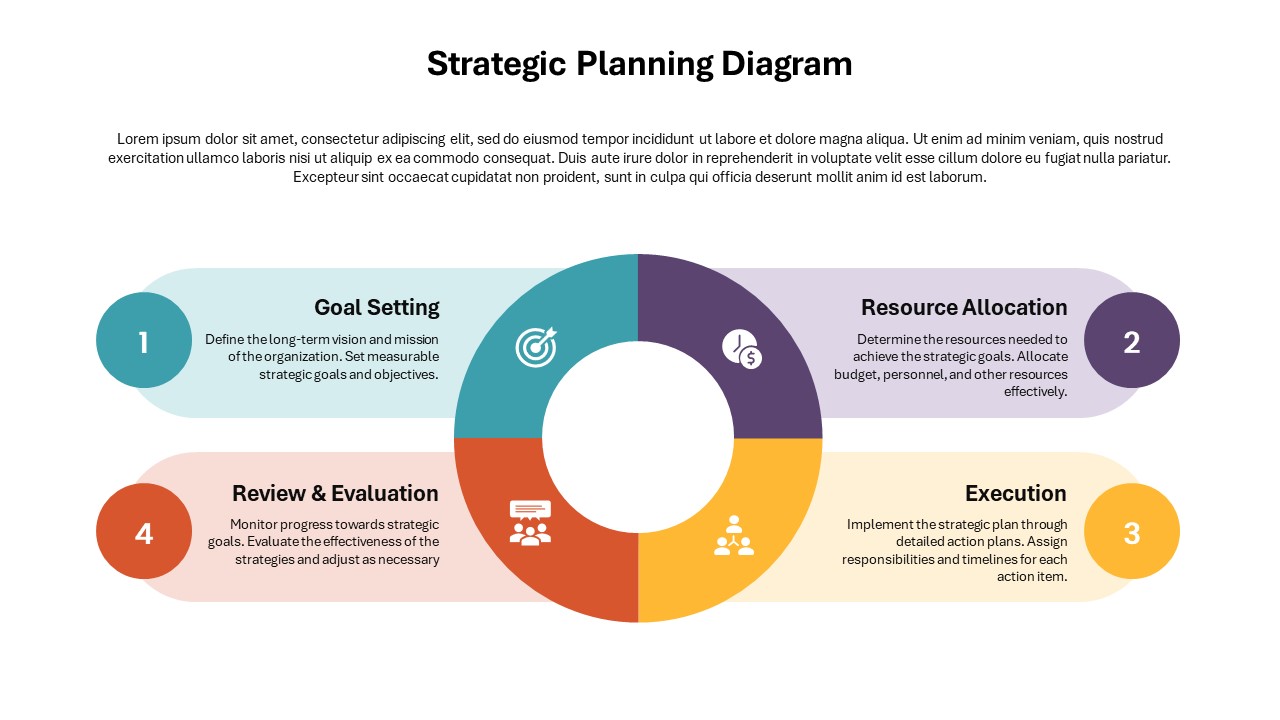

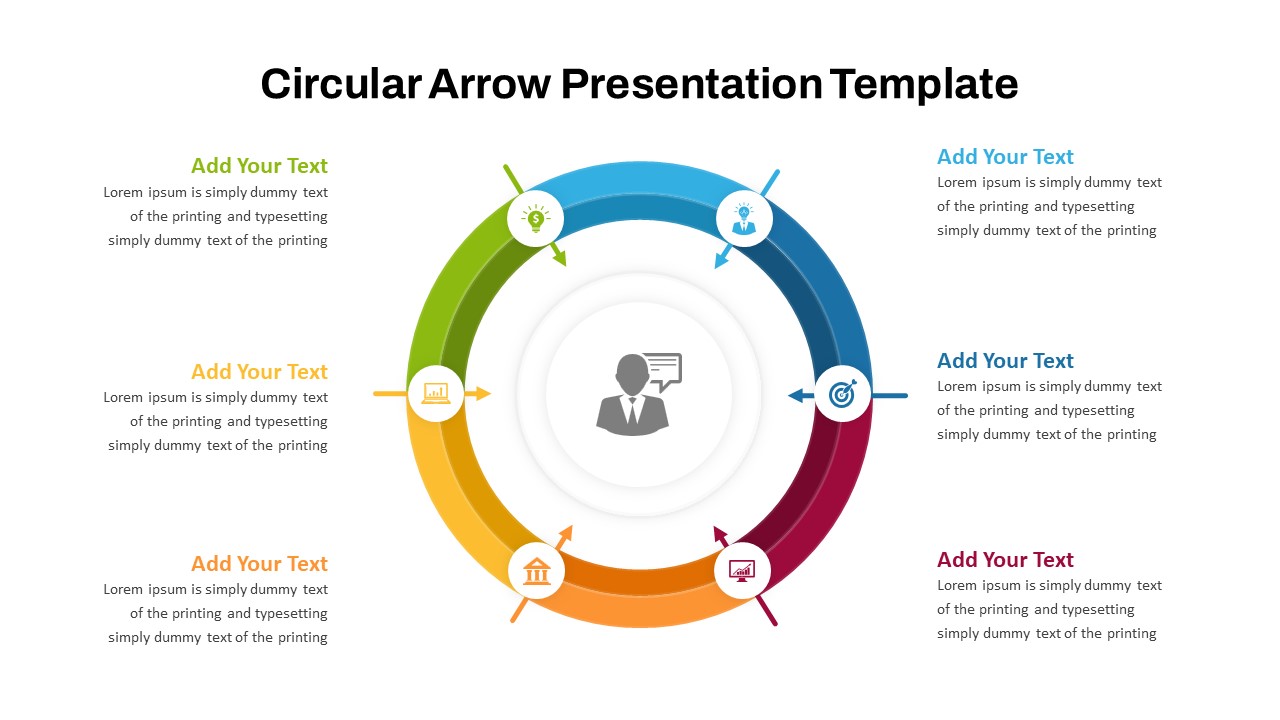

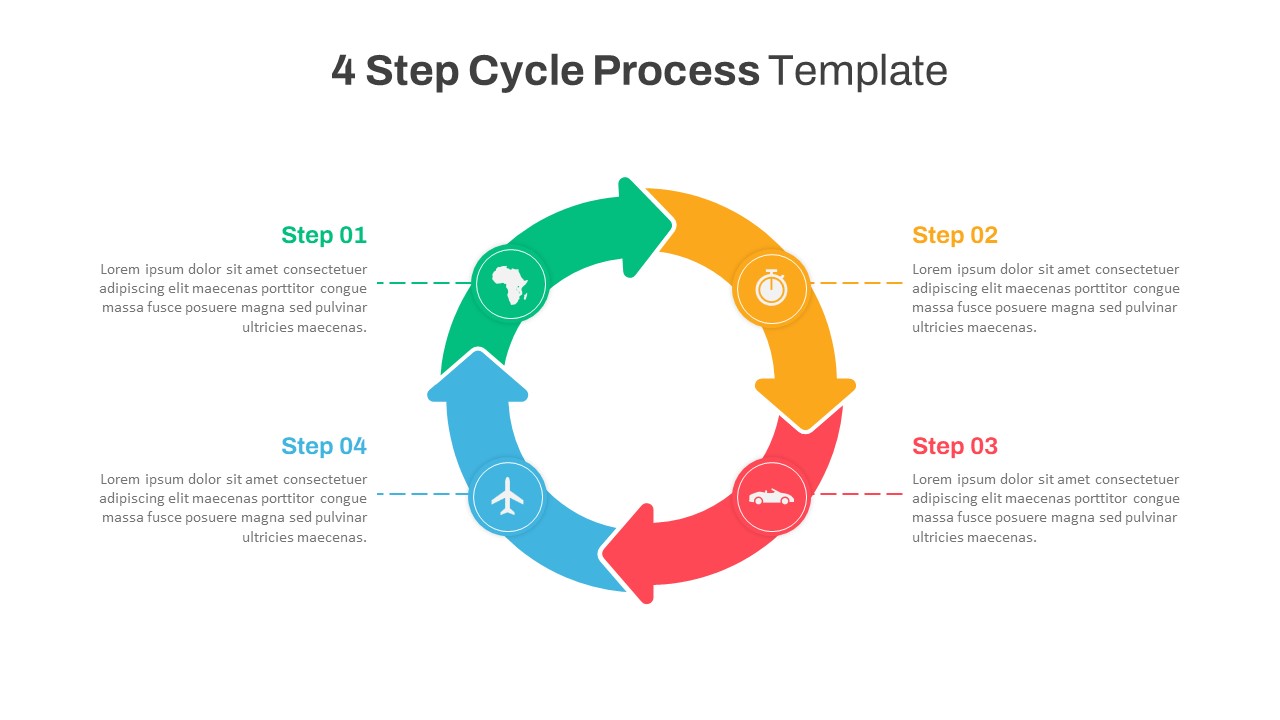

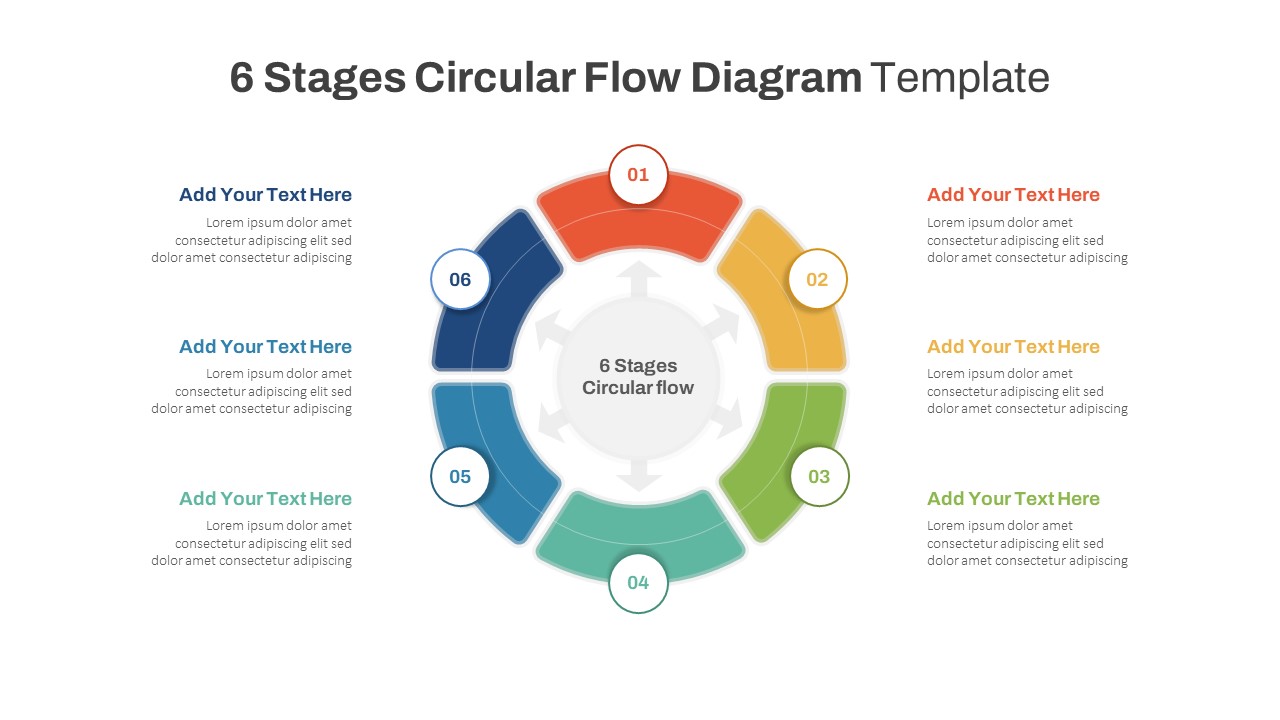

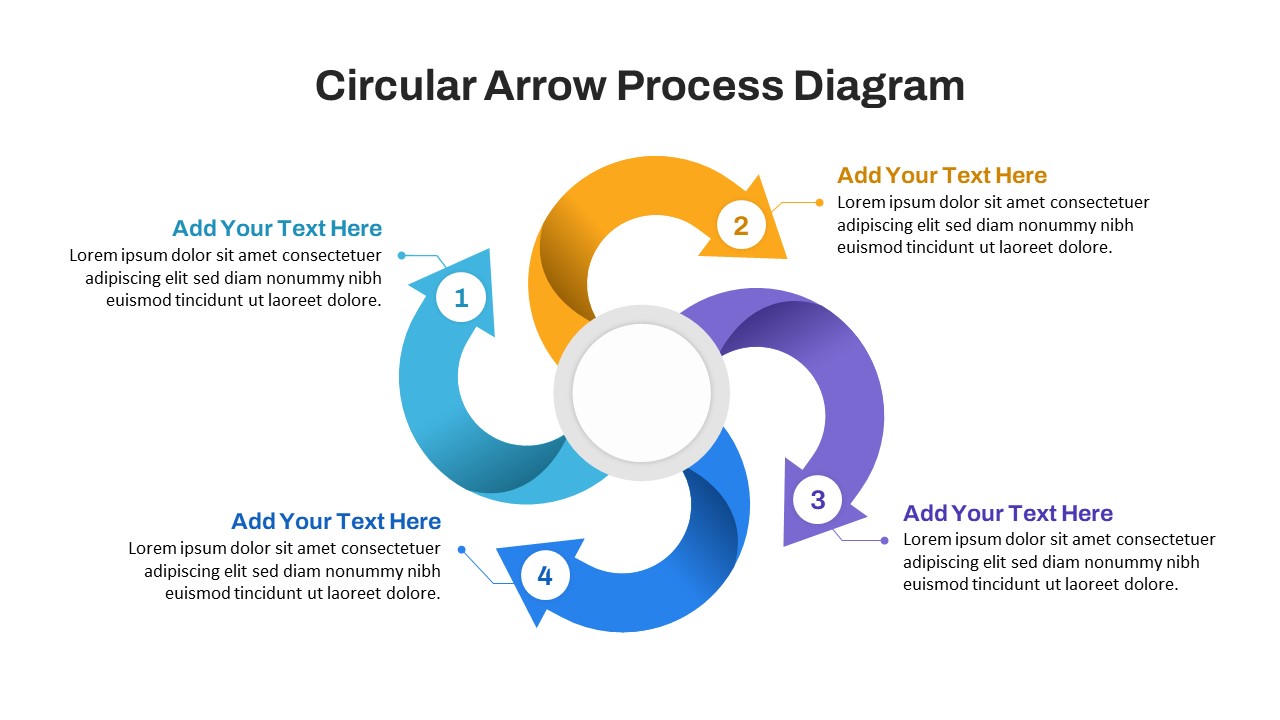

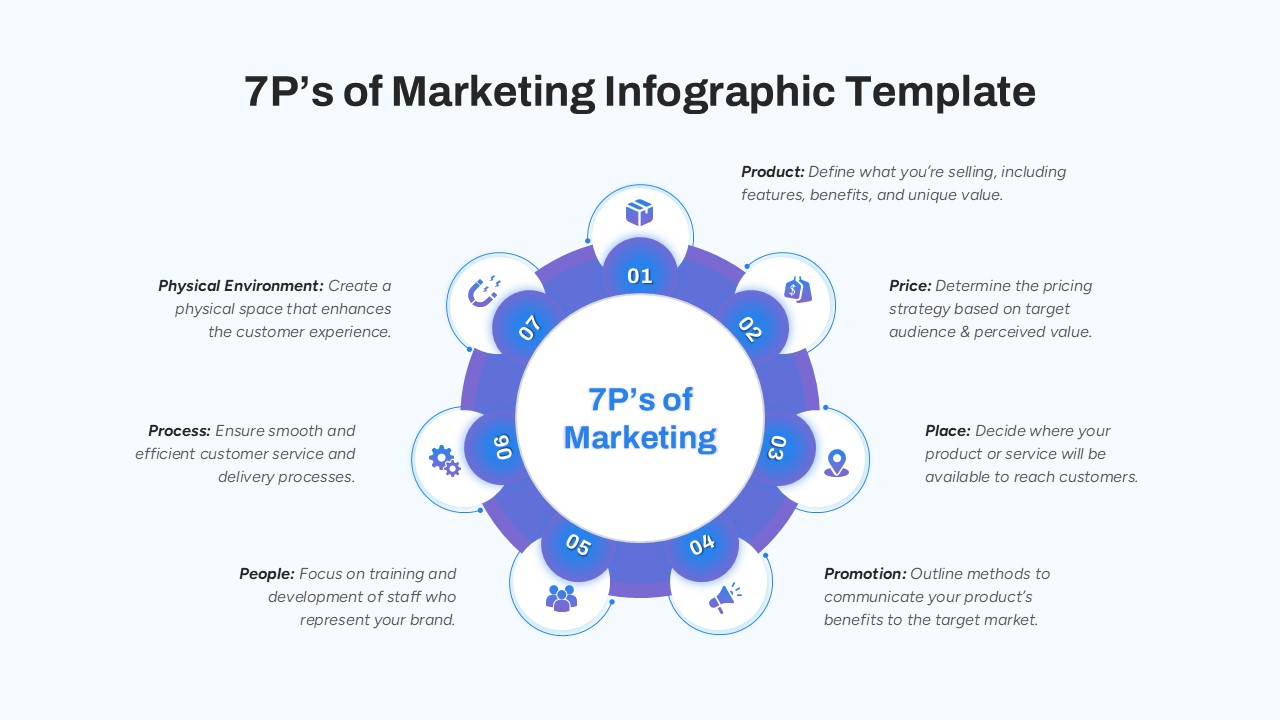

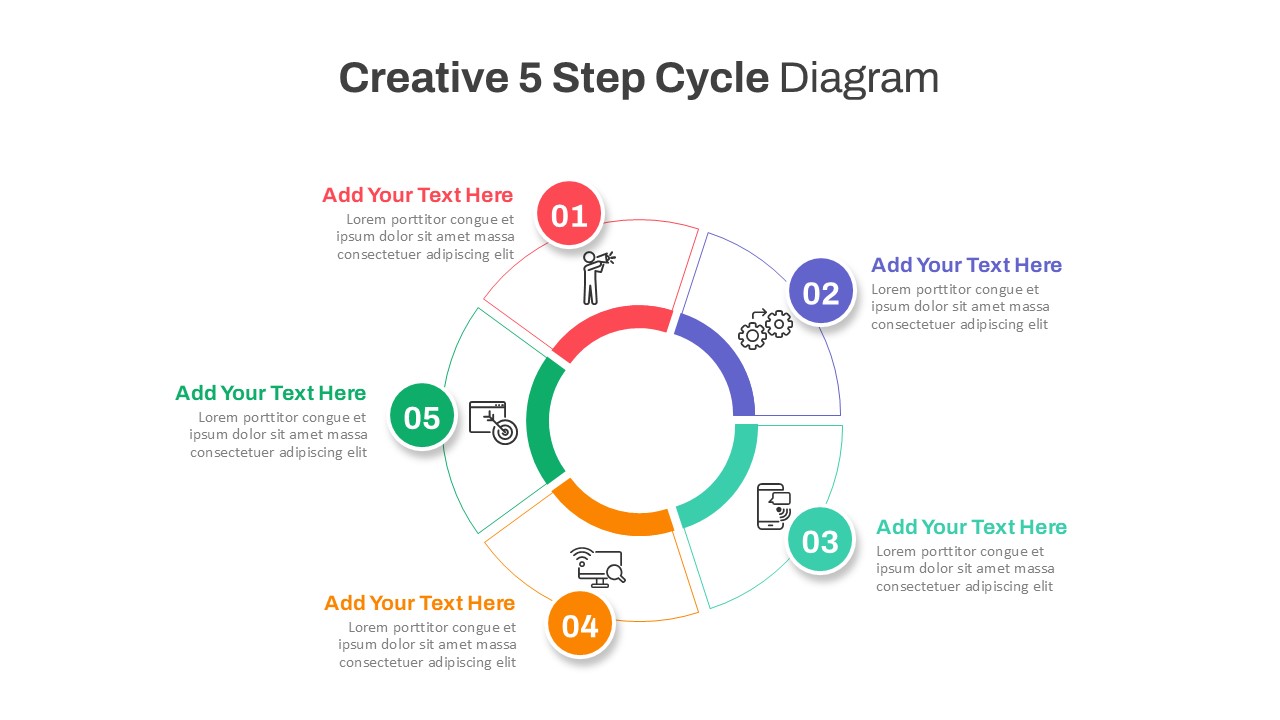

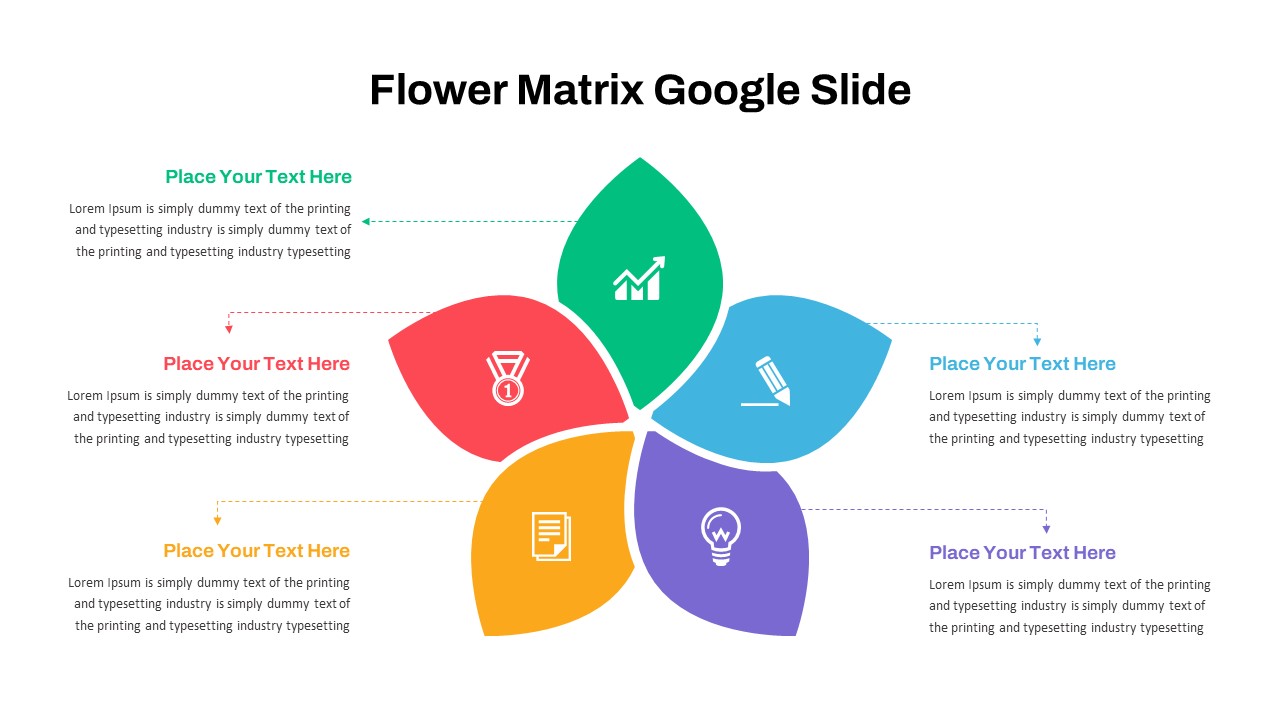

The Lean Manufacturing Template is a visually compelling and fully customizable tool designed to help businesses implement and explain lean manufacturing principles effectively. This PPT template highlights the five key stages of lean manufacturing: Defining Value, Value Stream Mapping, Creating Flow, Establishing Pull, and Continuous Improvement. Each stage is presented in a vibrant circular design, allowing users to convey concepts clearly and engage their audience.

With a focus on efficiency and waste reduction, this Lean Manufacturing Template is ideal for business leaders, project managers, and operational teams aiming to streamline production processes. The central icon symbolizes goal-oriented production, while the surrounding segments delve into actionable strategies to improve workflow and customer satisfaction.

Key features:

- Defining Value: Determine customer-centric value.

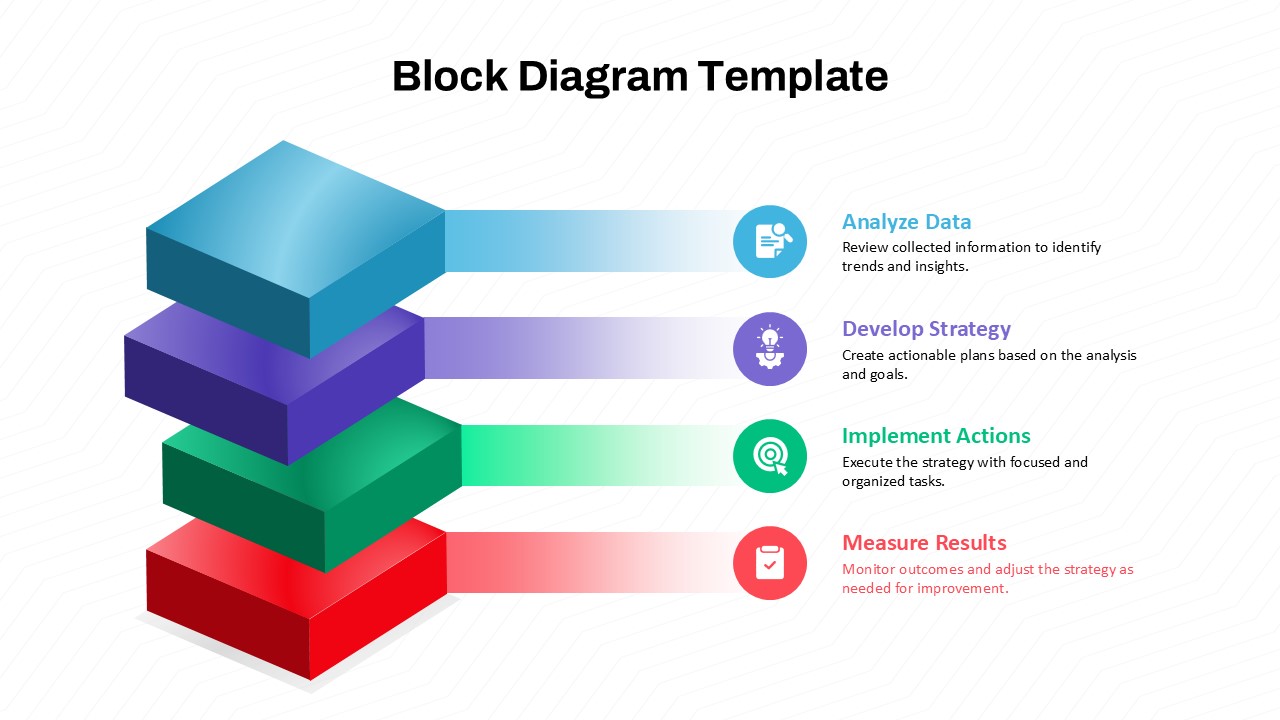

- Value Stream Mapping: Identify areas of waste and optimize steps in the value creation process.

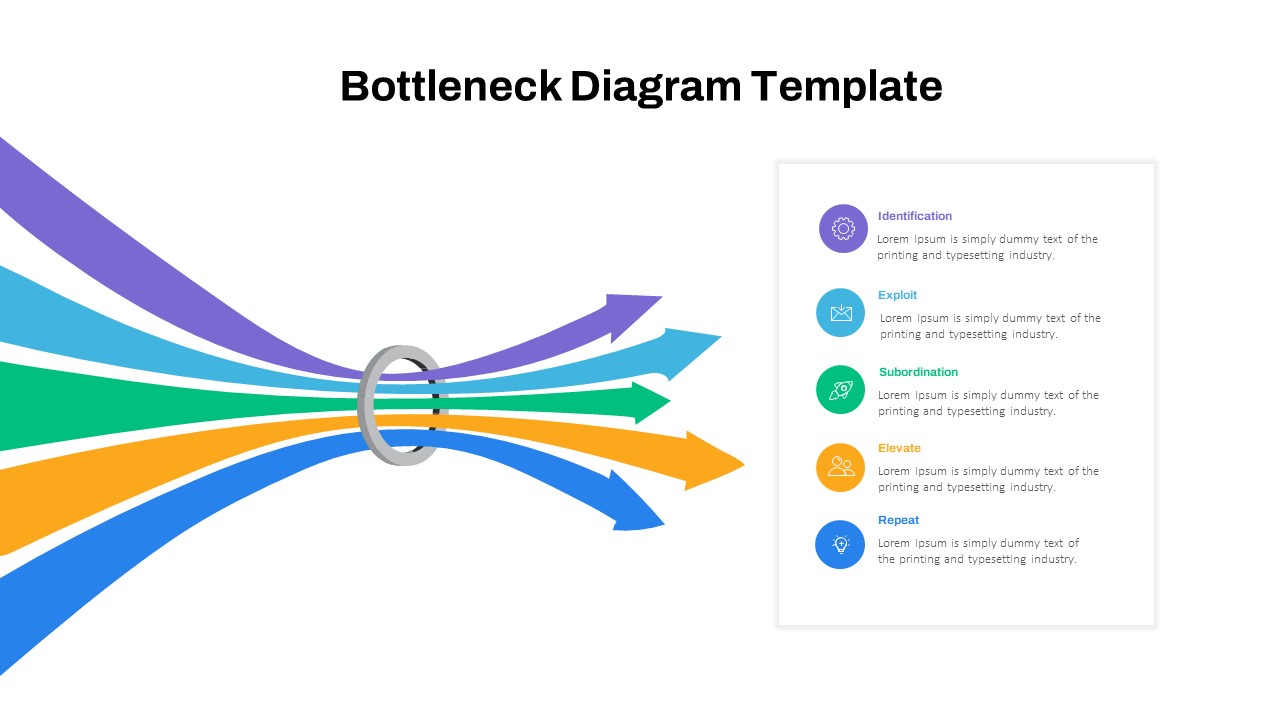

- Creating Flow: Ensure smooth production processes with minimal bottlenecks.

- Establishing Pull: Implement production strategies based on real-time demand.

- Continuous Improvement: Drive ongoing enhancements in systems and processes.

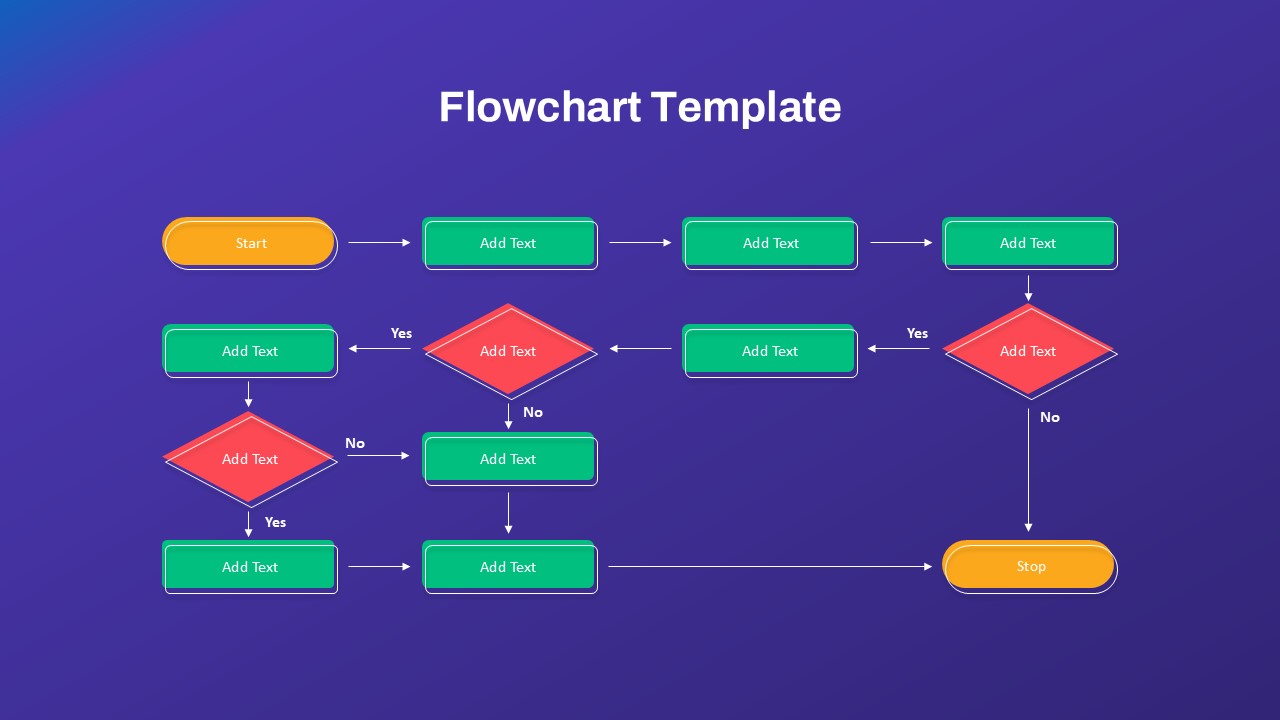

This template is fully editable in PowerPoint and Google Slides, enabling easy adaptation to fit any presentation style. Whether you’re introducing lean principles to your team, conducting training sessions, or mapping process improvements, this template offers a professional and streamlined solution to visualize your strategies.

See more